فهم بناء لوحة الشطيرة من الصوف الصخري

المواد الأساسية ومقاومة الحريق

يُصنع الصوف الصخري من صخور البازلت الطبيعية، ويُعرف بخصائصه الممتازة المقاومة للحريق، ويمكنه تحمل درجات حرارة تصل إلى 1200 درجة مئوية. تُعد هذه الدرجة العالية من مقاومة الحريق أمرًا بالغ الأهمية في البناء، خاصة في المباني التي يجب أن تتوافق مع معايير السلامة من الحريق الصارمة. تؤثر المواد الأساسية المستخدمة في لوحات ساندوتش التأثير ليس على العزل الحراري فحسب، بل أيضًا على سلامة هيكل اللوحة بشكل عام. تُعد هذه الناحية بالغة الأهمية لأنها تدعم متانة اللوحة وقدرتها على تحمل العوامل البيئية. إن اختيار المادة الأساسية الصحيحة، مثل الصوف الصخري، يوفر توازنًا بين السلامة والقوة والأداء العازل، مما يجعلها خيارًا شائعًا بين المهندسين المعماريين والبنائين الذين يركزون على إنشاء هياكل مقاومة للحريق.

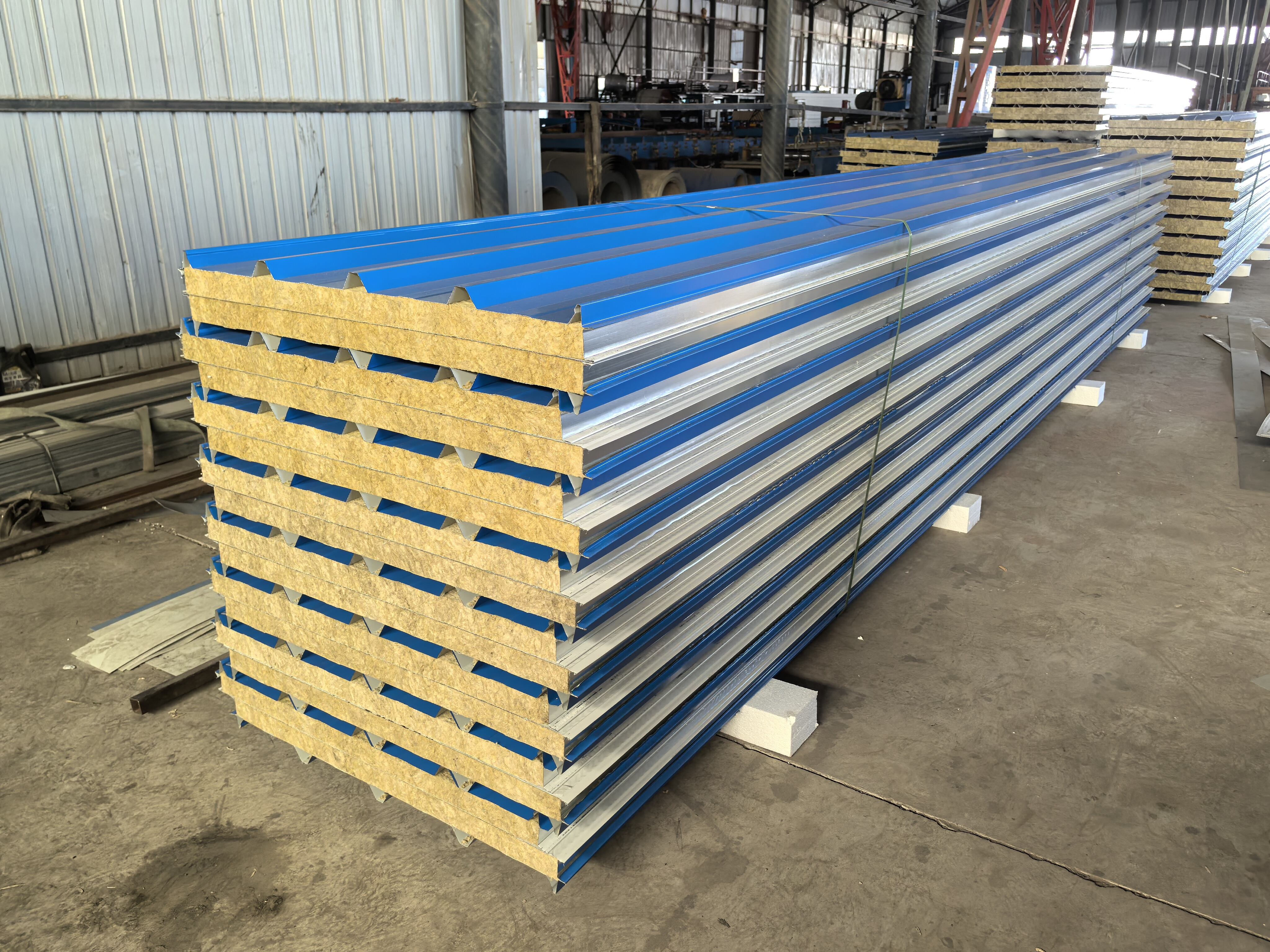

الطبقات السطحية والمتانة

تتميز الطبقات السطحية للوحة الشطيرة الصوفية عادةً باستخدام مواد مثل الصلب المجلفن أو الألومنيوم، مما يعزز مقاومتها للظروف البيئية. توفر هذه المواد حماية قوية ضد الرطوبة والتعرض لأشعة الشمس والعناصر الجوية الضارة الأخرى، مما يسهم بشكل كبير في متانة الألواح. تلعب المتانة دوراً أساسياً في هذه الألواح حيث تمد من عمرها الافتراضي، مما يوفر ادخاراً طويل الأمد في التكاليف من خلال تقليل الحاجة إلى الاستبدال والصيانة المتكررة. وفقاً للدراسات، فإن اختيار مواد سطحية عالية الجودة يمكن أن يزيد بشكل كبير من عمر هذه الألواح، مما يجعلها استثمارًا مربحًا للمشاريع المعرضة للظروف القاسية. إن التركيز على استخدام مواد بناء متينة هو أمر أساسي لضمان بقاء البنية التحتية قوية على مر الزمن، وبالتالي تعظيم الأداء والقيمة معاً.

مزايا الأداء الحراري والصوتي

تنظيم ثابت لدرجة الحرارة

تُعرف ألواح الصوف الصخري المُركبة بأنها تمتلك قدرة عزل حراري ممتازة، مما يضمن استقرار درجات الحرارة داخل المباني بغض النظر عن الظروف الخارجية القاسية. هذه الميزة مفيدة بشكل خاص من حيث الكفاءة في استخدام الطاقة، إذ تشير التقارير الصناعية إلى أن العزل الفعال يمكن أن يقلل من تكاليف التدفئة والتبريد بنسبة تصل إلى 30%. إن قدرة الصوف الصخري على تخفيف تقلبات درجة الحرارة تجعله خيارًا مستدامًا للبناء يُفضله من يركزون على البناء المعتمد على الكفاءة في استخدام الطاقة. إن خصائص الكتلة الحرارية للصوف الصخري لا تُسهم فقط في تنظيم درجات الحرارة بشكل ثابت، بل تُحسّن أيضًا الأداء الطاقي العام للمبنى.

قدرات تخفيض الضوضاء

ميزة أخرى كبيرة لألواح الصوف الصخري المركبة هي قدرتها المتميزة على تقليل الضجيج، وذلك بفضل الكثافة العالية للمواد المستخدمة من الصوف الصخري. على سبيل المثال، تشير الأبحاث إلى أن هذه الألواح قادرة على تقليل انتقال الضجيج بما يقارب 45 ديسيبل، مما يجعلها فعالة للغاية في خلق بيئات داخلية أكثر هدوءًا في المناطق الحضرية. ويجعل ذلك من ألواح الصوف الصخري خيارًا مثاليًا للمناطق القريبة من الطرق السريعة أو المطارات، حيث تساهم بشكل كبير في تحسين الراحة الصوتية للقاطنين. توفر خصائصها العازلة للصوت حلاً مثاليًا للمباني التي تكون فيها السيطرة على الضوضاء مصدر قلق رئيسي.

التطبيقات الصناعية والتجارية

حلول المستودعات والتخزين البارد

تلعب ألواح الصوف الصخري المركبة دورًا حيويًا في الحفاظ على درجات الحرارة في مرافق التخزين البارد، وهو أمر بالغ الأهمية لضمان سلامة المواد الحساسة للحرارة منتجات مثل الأغذية والمنتجات الصيدلانية. توفر هذه الألواح عزلًا حراريًا متفوقًا، مما يقلل من تقلبات درجة الحرارة داخل بيئة التخزين. علاوة على ذلك، يساعد استخدام الألواح الصوفية الصخرية في المستودعات في الامتثال لمتطلبات الجهات التنظيمية بالنسبة للمواد التي تحتاج إلى ظروف حرارية محددة. تعد التوفير في الطاقة ميزة كبيرة؛ حيث تشير الإحصائيات إلى أن استخدام الألواح الصوفية الصخرية في تطبيقات التخزين البارد يمكن أن يؤدي إلى توفير 40% من الطاقة بسبب تقليل الجسور الحرارية. هذه الحلول الموفرة للطاقة لا تقلل فقط من التكاليف التشغيلية، ولكنها تساهم أيضًا في تقليل الأثر البيئي.

تركيبات المباني التجارية

يُحسّن استخدام الألواح المركبة ذات الصوف الصخري في المباني التجارية كلًا من الجوانب الجمالية والوظيفية للهيكل. هذه الألواح متعددة الاستخدامات، مما يجعلها مناسبة للواجهات والتقسيم والسقف، مما يسمح بمرونة كبيرة في التصميم. بالإضافة إلى جاذبيتها البصرية، فإنها توفر فوائد كبيرة مثل العزل الحراري ومقاومة الحريق، مما يجعلها خيارًا مفضلًا في البناء الحديث. وقد أظهرت دراسات حالة متنوعة أن الألواح الصوفية يمكن أن تقلل من تكاليف البناء الإجمالية بنسبة تصل إلى 20٪ من خلال تبسيط عمليات البناء وتقليل الهدر. وبالتالي، تمثل هذه الألواح حلاً مثاليًا للمطورين الذين يسعون لتحقيق الكفاءة من حيث التكلفة مع الحفاظ على الأداء العالي في تركيبات المباني.

تقنيات التركيب لتحقيق أداء مثالي

اتجاه الألياف ومقاومة القص

إن التوجيه الصحيح للألياف داخل ألواح الصوف الصخري يُعد أمرًا بالغ الأهمية لتعزيز مقاومة القص والسلامة البنائية، خاصةً في التطبيقات ذات الإجهادات العالية. غالبًا ما تُبرز إرشادات التركيب أهمية توجيه الألياف بشكل محدد، مما يضمن قدرة الألواح على تحمل ظروف الأحمال المختلفة بكفاءة. يمكن أن تؤدي الألياف غير المحاذية بشكل صحيح إلى تهديد كبير لقدرة اللوحة على الحفاظ على الموثوقية البنائية، حيث أظهرت الدراسات حدوث فشل بنيوي محتمل ناتج عن مثل هذه سوء المحاذاة. من خلال الحفاظ على المحاذاة الصحيحة للألياف، يمكننا تحقيق مستوى الأداء المطلوب والمرونة البنائية لهذه الألواح.

تجنب الضغط والفجوات الهوائية

إن ضمان دقة التركيب أمرٌ بالغ الأهمية لتجنب ضغط الألواح، مما قد يؤثر على خصائصها العازلة. علاوة على ذلك، يمكن أن تؤدي الفجوات الهوائية بين الألواح إلى فقدان غير مرغوب للطاقة، مما يُفقِد الهدف من استخدامها في كفاءة الطاقة. إن تقنيات الإحكام الملائمة أثناء التركيب ضرورية للحفاظ على الأداء الأمثل وضمان الكفاءة في استخدام الطاقة. كما يُوصي الممارسات المُثلى في الصناعة أيضًا بإجراء فحوصات دورية بعد التركيب للتحقق من استمرارية فعالية الألواح وكشف أي فجوات هوائية أو ضغوط قد تظهر بمرور الوقت.

الاستدامة والقيمة على المدى الطويل

محتوى الرماد المعاد تدويره والتصميم الصديق للبيئة

تعتبر ألواح الصوف الصخري معترفًا بها بشكل متزايد لخصائص الاستدامة الخاصة بها، ويرجع ذلك أساسًا إلى محتواها العالي من الخبث المعاد تدويره. يسهم هذا الاختيار من المواد بشكل كبير في البناء المستدام من خلال تقليل النفايات في مكبات النفايات وتعزيز اقتصاد دائري. ومن خلال استخدام مواد معاد تدويرها، يقل تأثير الإنتاج على البيئة، مما يستجيب للطلب المتزايد على حلول بناء صديقة للبيئة. تشير الأبحاث إلى أن تقييم دورة حياة ألواح الصوف الصخري يؤدي إلى تأثير بيئي أقل بشكل ملحوظ مقارنة بالمواد البناء التقليدية. ويجعلها هذا خيارًا جذابًا لبناء المباني الخضراء المتوافقة مع معايير البيئة الحديثة.

عمر خدمة يزيد عن 40 عامًا مع صيانة محدودة

تُعتبر مدة الخدمة المُذهلة لألواح الصوف الصخري المُركبة من أبرز ميزاتها، حيث تتجاوز في كثير من الأحيان 40 عامًا. لا تُقلل هذه المدة الطويلة من الحاجة إلى عمليات الاستبدال المتكررة فحسب، مما يقلل من الأثر البيئي الناتج عن التخلص من المواد، بل تُسهم أيضًا في تحقيق وفورات كبيرة في التكاليف على المدى الطويل. وتزيد متطلبات الصيانة القليلة للألواح من جاذبيتها لأنواع مختلفة من المباني، بما في ذلك المباني السكنية والتجارية والصناعية. تشير الإحصائيات إلى أن الاستثمار في مواد متينة مثل الصوف الصخري يمكن أن يُحقق عوائد مالية كبيرة، مما يُبرز قيمتها كاستثمار طويل الأجل. وبجمعها بين المتانة وتكاليف الصيانة المنخفضة، تُعد ألواح الصوف الصخري حلاً اقتصاديًا مناسبًا للهندسة المعمارية المستدامة.

الأسئلة الشائعة

ما هي ألواح الصوف الصخري المُركبة وما هي فوائدها؟

لوحات الصوف الصخري المركبة هي مواد بناء تُصنع بقلب من الصوف الصخري، وتُعرف بمقاومتها للحريق والعزل والمتانة. وهي مفيدة للتصاميم المعمارية التي تركز على السلامة والكفاءة في استخدام الطاقة وتقليل الضوضاء والاستدامة.

كيف تساهم لوحات الصوف الصخري في السلامة من الحريق؟

لوحات الصوف الصخري تمتلك مقاومة عالية للحريق، ويمكنها تحمل درجات حرارة تصل إلى 1200 درجة مئوية، مما يجعلها مثالية للمشاريع الإنشائية التي تتطلب الالتزام بمعايير السلامة من الحريق الصارمة.

هل يمكن لوحات الصوف الصخري تعزيز الكفاءة في استخدام الطاقة؟

نعم، توفر لوحات الصوف الصخري عزلًا حراريًا ممتازًا، وتساعد في استقرار درجات الحرارة الداخلية، وقد تقلل من تكاليف التدفئة والتبريد بنسبة تصل إلى 30%، وبالتالي تعزز الكفاءة في استخدام الطاقة.

هل لوحات الصوف الصخري مناسبة لعزل الصوت؟

نعم، نظرًا لكثافة الصوف الصخري العالية، يمكن لهذه اللوحات تقليل انتقال الضوضاء بشكل كبير، مما يجعلها ممتازة لعزل الصوت في البيئات الحضرية الصاخبة.

EN

EN