Composite Design and Structural Efficiency

The Science of Composite Action in Sandwich Panels

The composite action in sandwich panels plays a crucial role in distributing loads effectively across different materials. This action ensures that the structural integrity of buildings is maintained while optimizing weight efficiency. The core material, often a lightweight foam or honeycomb structure, is pivotal in enhancing this efficiency. By providing rigidity and support between the two outer layers, the core helps in minimizing bending and enables the panel to withstand higher loads than traditional materials. In fact, projects that utilize sandwich panel technology have demonstrated significant improvements in load capacities. Notably, a study showed that sandwich panels could sustain up to twice the load of traditional solid panels, emphasizing their superiority in modern construction practices.

Continuous Lamination Techniques for Air Gap Sealing

Continuous lamination techniques are revolutionizing the way we create airtight seals in sandwich panels. This process involves the precise layering of materials, which results in a uniform thickness and significantly reduces manufacturing defects. Technological advancements have furthered this process, allowing for greater consistency and enhanced performance of the panels. Interestingly, studies have demonstrated that these techniques lead to notable improvements in energy performance. By effectively sealing air gaps, these panels contribute to more energy-efficient buildings, reducing the need for artificial heating and cooling. Such advancements not only optimize energy use but also align with growing regulatory demands for sustainability.

Long-Span Capabilities Reducing Secondary Framing Needs

The long-span capabilities of sandwich panels are transforming architectural practices by reducing the need for secondary framing structures. These panels can cover greater distances without additional support, which simplifies construction and leads to considerable cost savings. For instance, several case studies have shown that the reduction in secondary framing can cut material costs by up to 30% and shorten construction times significantly. This efficiency allows architects and builders to explore innovative design solutions without compromising on structural integrity. Long-span panels thus offer a compelling blend of aesthetic flexibility and construction efficiency, marking a significant shift in modern construction methodologies.

Advanced Thermal Insulation Performance

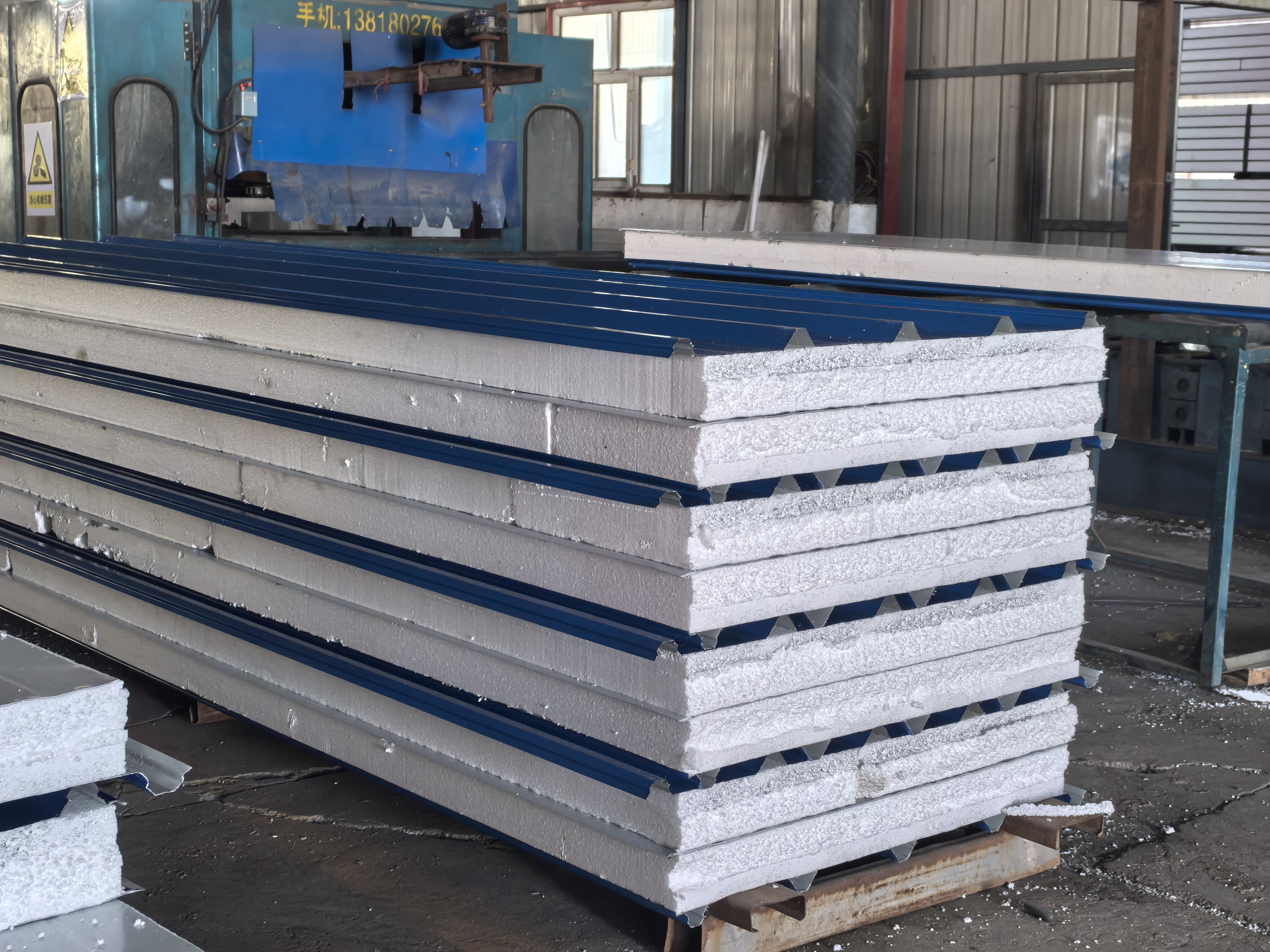

Polyurethane Core's R-7 Efficiency Per Inch

The thermal efficiency of polyurethane cores in sandwich panels is noteworthy, primarily due to their R-7 rating per inch. This efficiency surpasses many other insulation materials, contributing to substantial energy cost savings in building construction. The R-value measures the material's thermal resistance, indicating its capacity to resist heat flow. Higher R-values are instrumental in lowering heating and cooling costs, emphasizing the importance of efficient insulation. In real-world applications, studies show that polyurethane cores deliver up to 30% more energy savings compared to traditional insulation materials, thereby reinforcing their value in sustainable construction practices.

Eliminating Thermal Bridges Through Sealed Construction

Thermal bridges can significantly compromise the effectiveness of insulation by allowing heat to escape through gaps in construction materials. Sandwich panels address this issue through sealed construction techniques that effectively eliminate thermal bridges, enhancing overall energy efficiency. The construction of sandwich panels involves continuous layers that create a seamless barrier against heat transfer. Experts highlight that sealed constructions can enhance building energy efficiency by up to 25%, as they prevent heat loss and maintain a more stable indoor temperature, leading to improved thermal comfort and reduced energy consumption.

Meeting Global Energy Codes and Standards

Sandwich panels with advanced insulation properties are aligned with global energy codes and standards, ensuring compliance for builders worldwide. These panels facilitate adherence to regulations like the International Energy Conservation Code (IECC) and the European Union’s directives on energy performance. Their superior insulation capabilities meet and often exceed the mandatory requirements for thermal performance. Documented cases of successful certifications through the use of sandwich panels highlight their role in achieving energy efficiency certificates, thus making them an essential choice for construction projects aiming to meet stringent global energy standards.

Fire Safety and Environmental Resistance

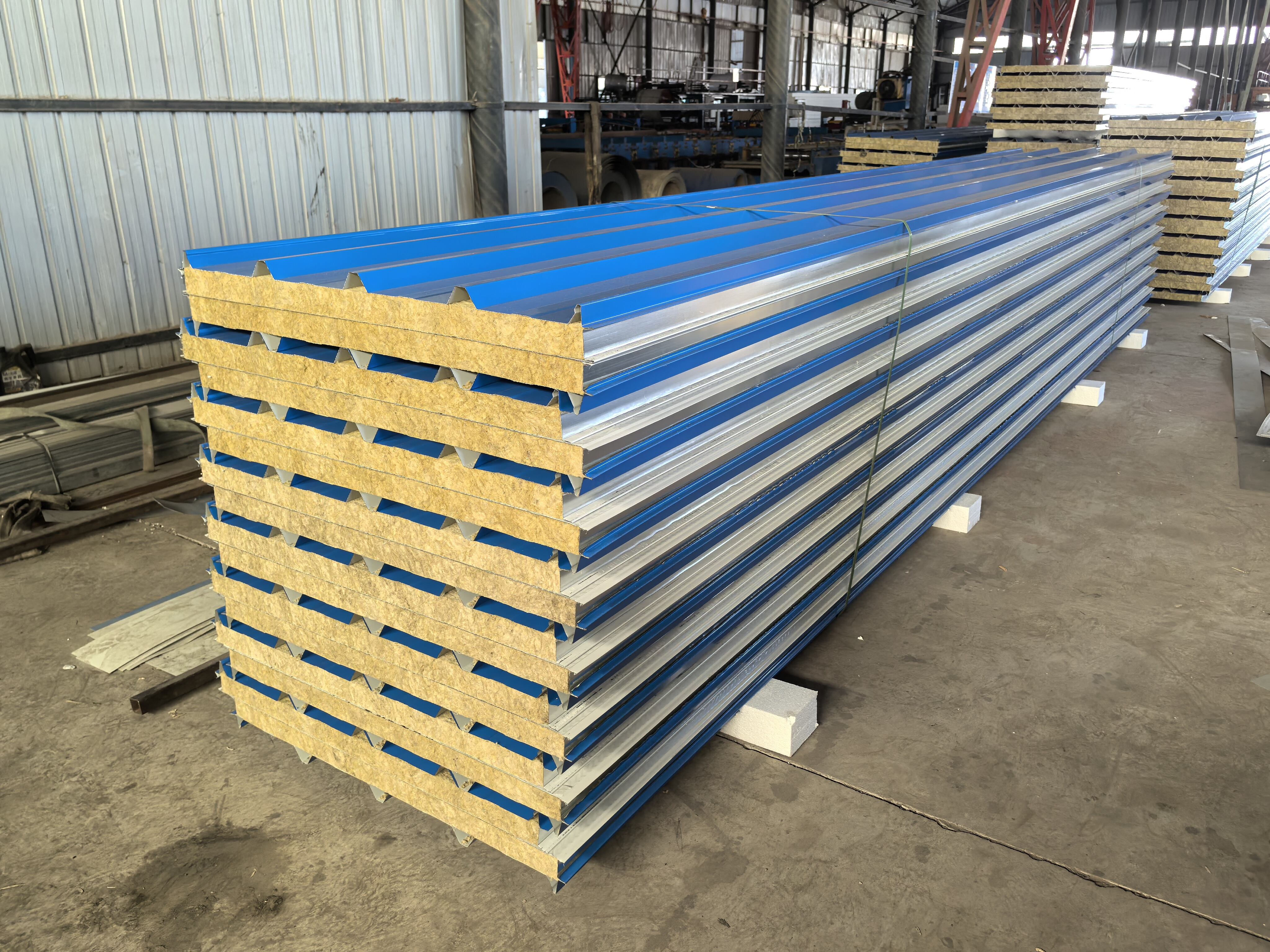

Fire-Retardant Core Materials and Safety Compliance

Fire safety in sandwich panels is paramount, and it's achieved by incorporating advanced fire-retardant core materials such as mineral wool and polyisocyanurate (PIR). These materials are specifically designed to resist ignition and slow the spread of flames, providing crucial time for evacuation and firefighting. Compliance with safety regulations is critical to ensure that buildings using these panels can withstand fire hazards effectively. For example, sandwich panels with fire-retardant cores must meet stringent fire resistance standards, serving as a testament to their effectiveness in real-world scenarios. Case studies have shown that constructions utilizing these panels performed remarkably well during fire incidents, minimizing damage and enhancing overall safety.

Moisture-Resistant Properties for Harsh Environments

Sandwich panels are engineered with moisture-resistant properties that allow them to withstand harsh environmental conditions without degradation. These panels prevent moisture ingress, protecting structural integrity and reducing the risk of mold and corrosion. Rigorous testing methods, such as exposure to high humidity and condensation, have demonstrated their exceptional performance in keeping interiors dry even in the most challenging environments. When compared to traditional building materials, sandwich panels clearly outperform due to their ability to repel moisture, resulting in enhanced durability and long-term performance. This makes them particularly suitable for facilities exposed to high-moisture situations, such as food storage or agricultural buildings.

Durability in Extreme Weather Conditions

Sandwich panels are renowned for their durability in extreme weather conditions, from powerful winds to heavy snowfall and torrential rains. Built with robust outer skins and the insulation prowess of their cores, these panels maintain their structural integrity regardless of external climate challenges. Studies and field data consistently show that buildings utilizing sandwich panels have superior longevity, often exceeding expectations when it comes to weather resistance. This durability is further emphasized by industry recommendations that align panel design with climatic data to maximize resilience. By prioritizing such best practices, construction projects can ensure unmatched reliability and longevity in environments susceptible to extreme weather events.

Aesthetic Flexibility and Economic Advantages

Pre-Finished Color-Coated Surfaces for Instant Aesthetics

Pre-finished color-coated surfaces offer significant aesthetic and practical benefits for sandwich panels. The ready-to-use surfaces provide an immediate appeal, eliminating the need for extensive on-site finishing, which means projects can be completed faster and with less hassle. These panels come in a broad spectrum of color options and finishes, allowing architects and designers to exercise creativity and align the aesthetic of a building with its intended style and purpose. The flexibility in colors and finishes means that sandwich panels can seamlessly blend with or stand out from the surrounding environment, providing versatile design opportunities.

Many architects have praised the aesthetic value of sandwich panels. Testimonials often highlight how these panels transform ordinary surfaces into visually pleasing elements, providing both modern and classic looks depending on the chosen finishes. This capability has been particularly well-received in both residential and commercial projects where visual impact is key.

Cost Savings from Reduced Labor and On-Site Painting

The financial benefits of using pre-finished sandwich panels are significant. By incorporating pre-finished surfaces, these panels drastically reduce the labor costs and time associated with painting. This is because they arrive on-site ready for installation, eliminating the need for additional on-site labor to paint and finish the panels. When compared to traditional building materials, where painting and finishing are necessary steps, the use of sandwich panels can result in notable cost savings.

Data from numerous projects have shown a marked decrease in expenses due to reduced labor and shorter project timelines. For example, a number of construction projects using sandwich panels reported savings of up to 20% on labor costs. Additionally, the streamlined process means the overall project timeline is shortened, enabling faster completion and earlier occupancy, which can lead to quicker returns on investment. This makes sandwich panels not only an aesthetically flexible choice but also a highly economical one.

Modern Applications Across Industries

Commercial and Industrial Building Solutions

Sandwich panels play a pivotal role in the construction of commercial spaces and industrial facilities, due to their robust and versatile characteristics. These panels excel in structural performance and IT compliance, offering energy efficiency and structural integrity. Businesses in various sectors, from retail chains to large warehouses, have successfully upgraded their infrastructure using sandwich panels. For instance, many shopping centers and manufacturing facilities have adapted these panels to meet industry standards for both structural and thermal performance. As a result, they not only support sustainable practices but also enhance overall building efficiency.

Cold Storage Facilities and Temperature-Controlled Environments

The efficiency of sandwich panels in cold storage construction is unparalleled, thanks to their outstanding insulation properties. Reinforced with materials like polyurethane and mineral wool, these panels ensure precise temperature control and energy savings. A case study from a major food distribution company demonstrated that switching to sandwich panels reduced energy costs by 15%. Experts emphasize the importance of maintaining temperature accuracy in cold storage, as even slight variances can impact product quality. The insulation provided by sandwich panels is crucial for conserving energy and maintaining product integrity, especially for perishable goods.

Modular Construction for Rapid Project Completion

In the realm of modular construction, sandwich panels are game-changers due to their ease of installation and efficiency. Modular construction is a growing trend, particularly in sectors where time is of the essence, such as healthcare and education. According to industry data, using sandwich panels in modular builds can reduce project timelines by up to 30%. Their lightweight nature coupled with quick installation processes allows construction projects to move swiftly from planning to completion. As modular building methods continue to gain traction, sandwich panels provide the ideal solution for accelerating project timelines while maintaining quality and durability.

FAQ

What are sandwich panels used for?

Sandwich panels are used in construction for their structural efficiency, energy performance, and aesthetic flexibility. They are ideal for applications in commercial buildings, cold storage, and modular construction.

How do sandwich panels improve energy efficiency?

Sandwich panels enhance energy efficiency through their high insulation properties and ability to eliminate thermal bridges, thereby reducing heating and cooling costs.

Are sandwich panels durable?

Yes, sandwich panels are designed to withstand harsh environmental conditions, including extreme weather, moisture, and fire. Their durable nature makes them a preferred choice for sustainable construction.

What materials are commonly used in sandwich panels?

Common materials used in sandwich panels include polyurethane, mineral wool, and polyisocyanurate for the core, combined with pre-finished outer layers for aesthetic and practical benefits.

EN

EN